What are the different types of print on a T-Shirt?

In this article, we will explore four popular t-shirt printing methods: HTV T-Shirt Printing, Screen Printing T-Shirts, Dye Sublimation, and Printed Transfer Paper. With over 20 years of experience in the industry, we'll provide you with a unique and in-depth look at each method, explaining the processes involved and their pros and cons.

HTV T-Shirt Printing

Process

Heat Transfer Vinyl (HTV) t-shirt printing is a method that involves cutting designs from sheets of vinyl and then applying them to the fabric using heat and pressure. A vinyl cutter is used to cut out the desired design, which is then weeded to remove excess material. Finally, a heat press or an iron is used to apply the design onto the t-shirt.

Pros

- Durability: HTV designs are known for their durability and ability to withstand multiple washes without fading or peeling.

- Versatility: This method is suitable for various fabrics and materials, including cotton, polyester, and blends.

- Precision: The vinyl cutter allows for intricate and precise designs.

Cons

- Limited Colors: The HTV method can be limiting when it comes to colour options, as each colour must be cut and applied separately.

- Time-Consuming: The process of cutting, weeding, and pressing each design can be labour-intensive, especially for large orders.

- Cost: The cost of vinyl material and equipment may be prohibitive for small-scale or one-time projects.

Screen Printing T-Shirts

Process

Screen printing, also known as silk screening, is a traditional t-shirt printing method that involves using a stencil (the screen) to apply ink directly to the fabric. A design is created on a mesh screen, with non-printing areas blocked by a substance called emulsion. Ink is then pushed through the open areas of the screen onto the t-shirt.

Pros

- High Quality: Screen printing produces crisp, clear, and long-lasting designs.

- Cost-Effective: This method is economical for large orders, as the same screen can be used multiple times.

- Vibrant Colors: Screen printing allows for bright and vivid colors, even on dark fabrics.

Cons

- Complex Set-Up: Creating screens for each design can be time-consuming and requires a certain level of skill.

- Limited Design Complexity: Fine details or photographic images may be difficult to reproduce using screen printing.

- Inefficient for Small Orders: Due to the initial set-up costs, screen printing may not be cost-effective for small quantities.

Dye Sublimation

Process

Dye sublimation is a digital printing technique that uses heat-sensitive ink to transfer designs onto fabric. The design is first printed onto a special transfer paper using sublimation ink. Then, a heat press is used to transfer the ink from the paper to the t-shirt, where it turns into a gas and bonds with the fabric's fibers.

Pros

- High-Quality Images: Dye sublimation allows for photo-realistic and intricate designs with no loss of detail.

- No Hand Feel: The ink bonds with the fabric, resulting in a smooth finish without any added texture.

- Durability: The designs are resistant to fading, peeling, and cracking.

Cons

- Limited to Polyester: Dye sublimation works best on polyester or polyester blend fabrics, which may not be ideal for all preferences.

- Cost: The equipment and materials required for dye sublimation can be expensive, making it less suitable for small-scale or one-time projects. 3. Ineffective on Dark Fabrics: Dye sublimation is not well-suited for dark-coloured fabrics, as the inks are not opaque and may appear dull or washed out.

Printed Transfer Paper

Process

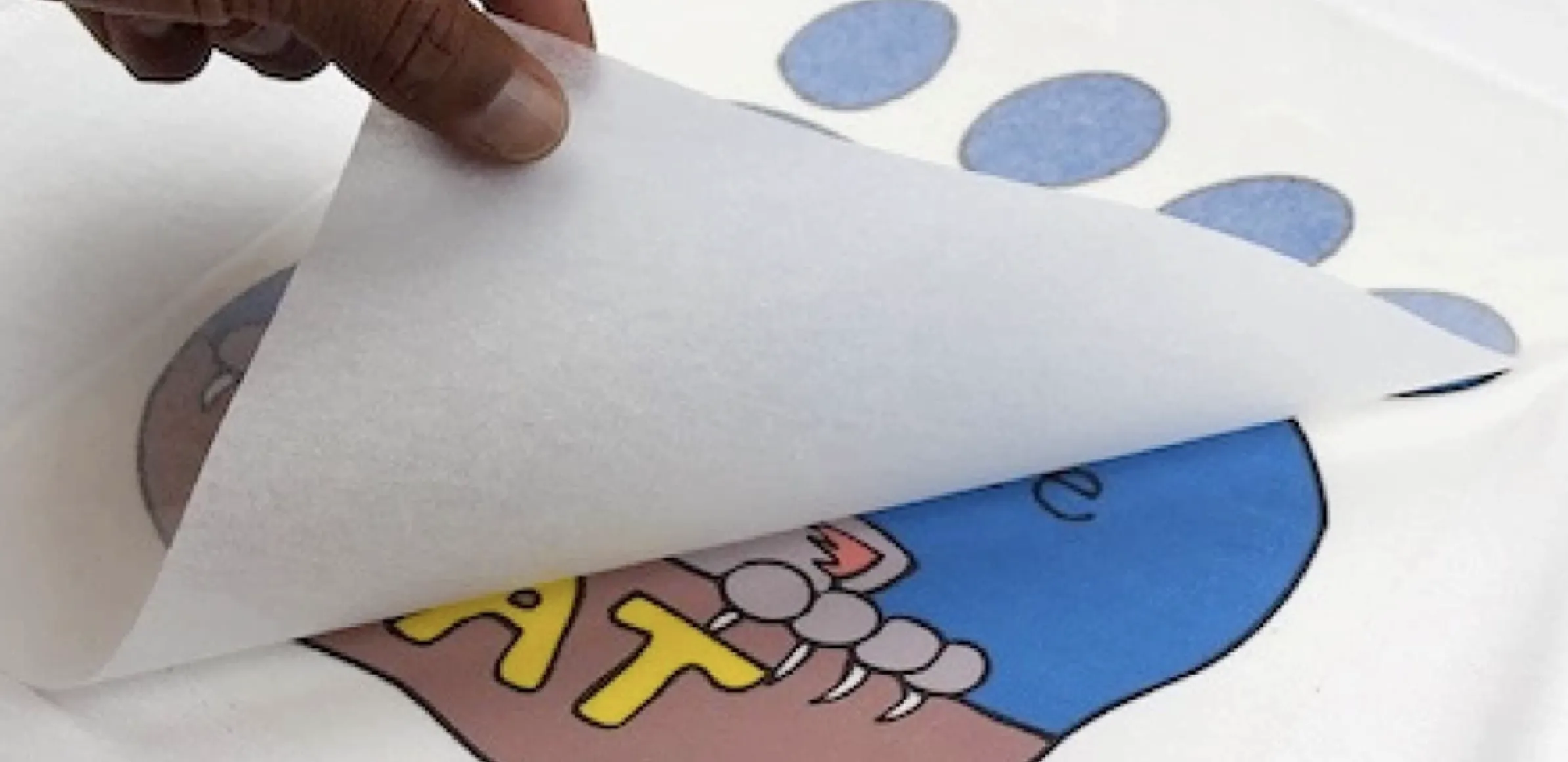

Printed transfer paper involves printing a design onto a special paper and then transferring it onto the t-shirt using heat and pressure. The design is first printed onto the transfer paper using a standard inkjet or laser printer. Afterwards, the printed design is placed onto the t-shirt, and a heat press or iron is used to apply heat and pressure, causing the design to transfer onto the fabric.

Pros

- Accessibility: This method is easy to use and requires minimal equipment, making it ideal for DIY projects or small-scale production.

- Design Flexibility: Printed transfer paper allows for complex, multicoloured designs, including photographs and detailed images.

- Quick Set-Up: The process requires little preparation, making it suitable for on-demand or personalized printing.

Cons

- Durability Concerns: Designs created using printed transfer paper may be less durable than other methods and prone to fading, cracking, or peeling over time.

- Hand Feel: The transferred design may have a noticeable texture or thickness on the fabric, which some people may find undesirable.

- Inefficient for Large Orders: The process of printing and applying each transfer can be time-consuming, making it less efficient for large-scale production.

Direct-to-Film (DTF) Printing

Process

Direct-to-film (DTF) printing is a relatively new t-shirt printing technique that involves printing designs directly onto a film, which is then transferred onto the fabric using heat and pressure. The design is first printed onto a special film using a DTF printer that utilizes specialized ink and adhesive powder. Once the film is ready, it is positioned onto the t-shirt, and a heat press or an iron is used to transfer the design onto the fabric.

Pros

- High-Quality Images: DTF printing allows for intricate, detailed designs and photo-realistic images with vibrant colours.

- Versatility: This method is compatible with various fabric types, including cotton, polyester, and blends, and works well on both light and dark-coloured fabrics.

- No Hand Feel: The transferred design bonds with the fabric, resulting in a smooth and soft finish without any noticeable texture.

Cons

- Cost: The specialized DTF printers and materials can be expensive, which may be a barrier for small-scale projects or one-time use.

- Time-Consuming: The process of printing and applying each design can be labour-intensive, particularly for large orders.

- Durability: While DTF prints are generally durable, they may be slightly less long-lasting compared to methods like screen printing or HTV.

Which is the best printing method for Car T-Shirts / Clothing?

The question is not as easy as it seems. For me, I always found HTV Vinyl the best for the types of T-shirts I make - however, it does come with limitations. HTV allows me to keep stock of blank t-shirts and gives my customers a choice of colours without requiring me to incur large setup fees.

I absolutely love full-colour designs, however, I have always felt screen printing lacks durability and is prone to cracking and fading - this obviously depends on the quality of the material.

For large runs of t-shirts, all with the same design, screen printing is definitely more cost-effective, whilst for smaller personalised printing HTV or Sublimation is the clear winner.

we may earn a commission if you click through and make a purchase.